Torque limiters, also known as clutches, are a key driveline component. They instantly disengage the drive when excessive torque is detected, safeguarding equipment from potentially damaging overloads that can cause costly repairs and downtime.

To choose the right torque limiter for your application, consider:

-

- Torque range

- Application disconnect frequency and duration

- Transmitted torque during disconnect

- Re-engagement method

- Cost of ownership

Types of Clutches

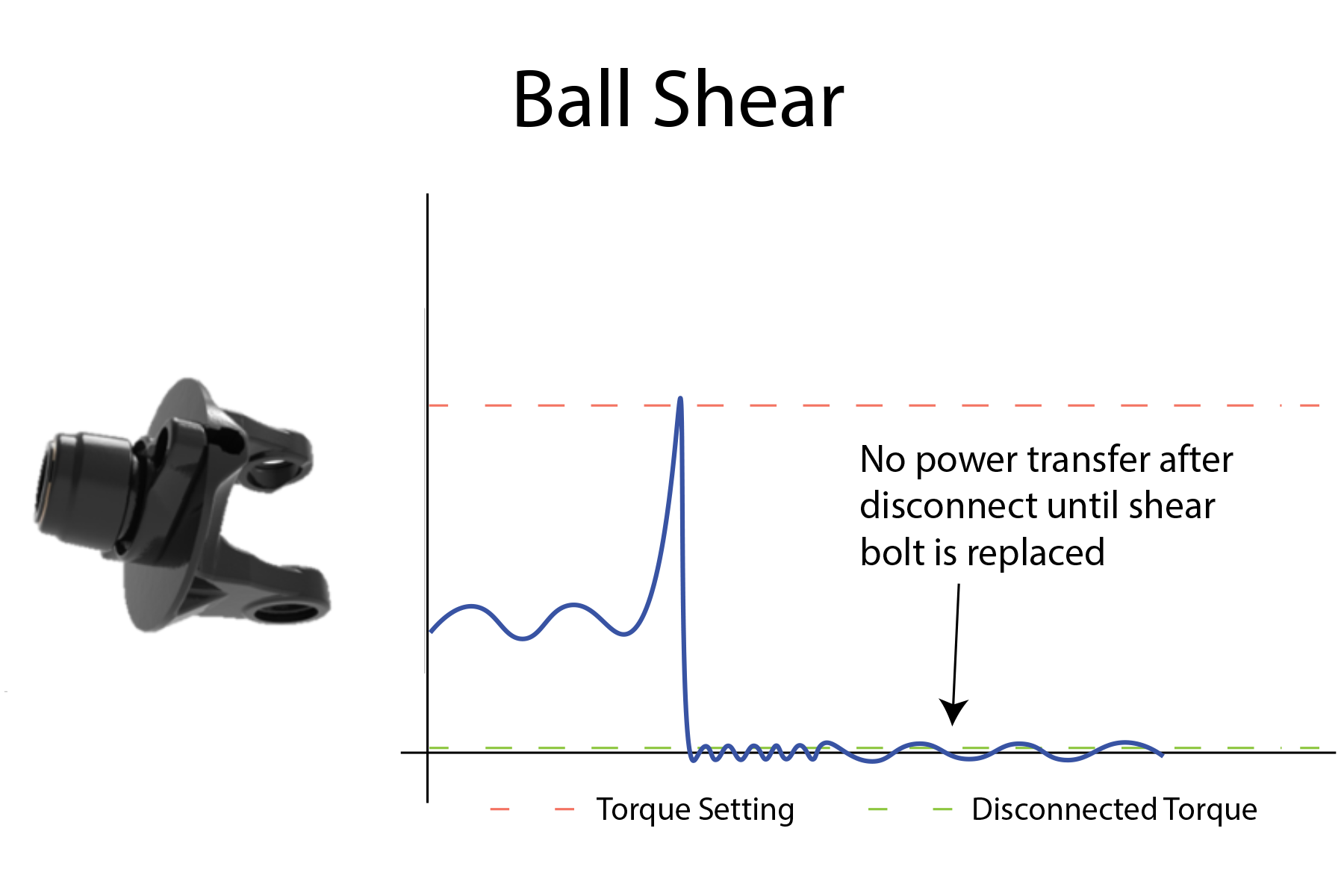

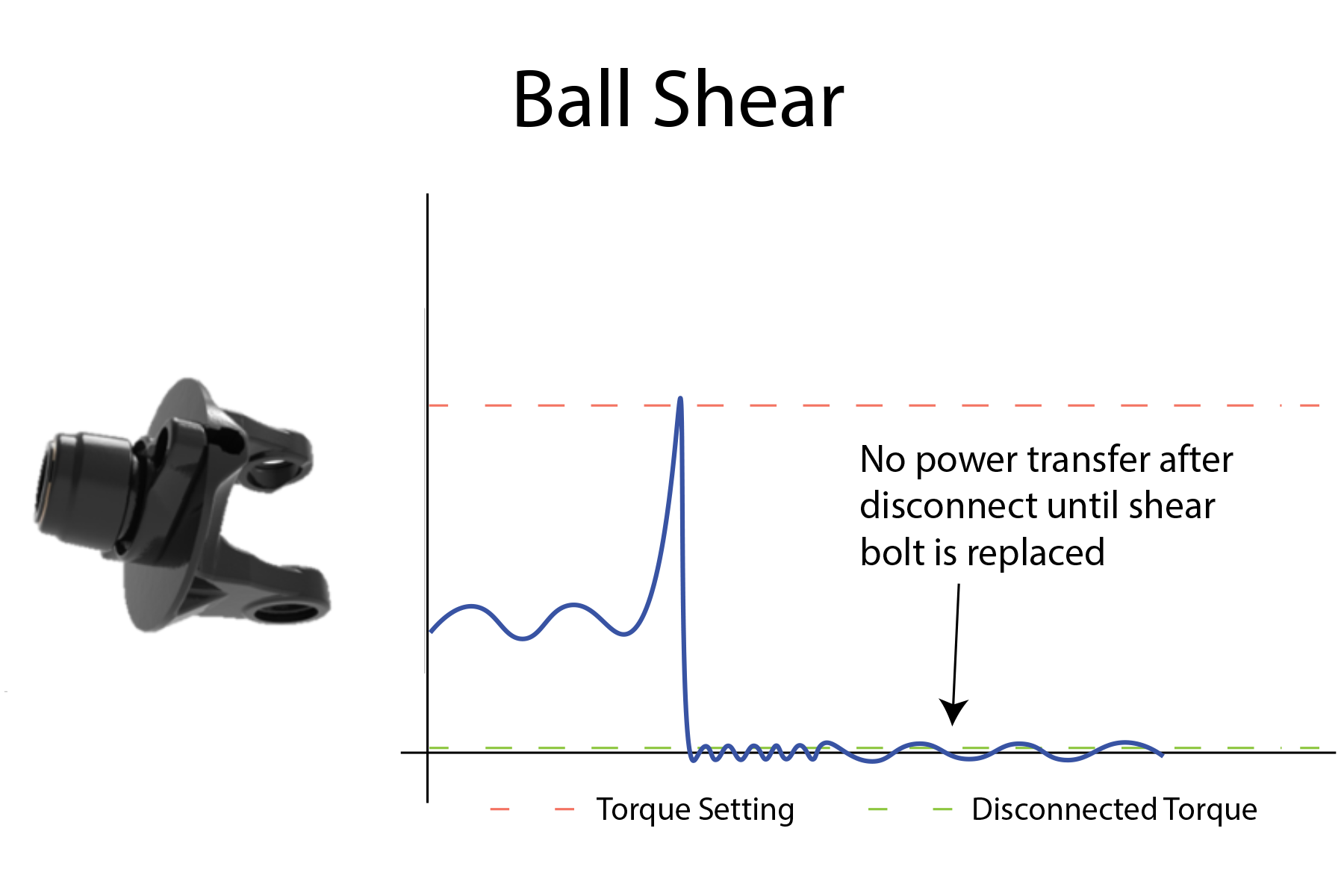

Ball Shear

Application examples include snowblowers, grain augers, manure spreaders, mixer feeders and bale processors.

Learn more by reading our Ball Shear Brochure.

|

|

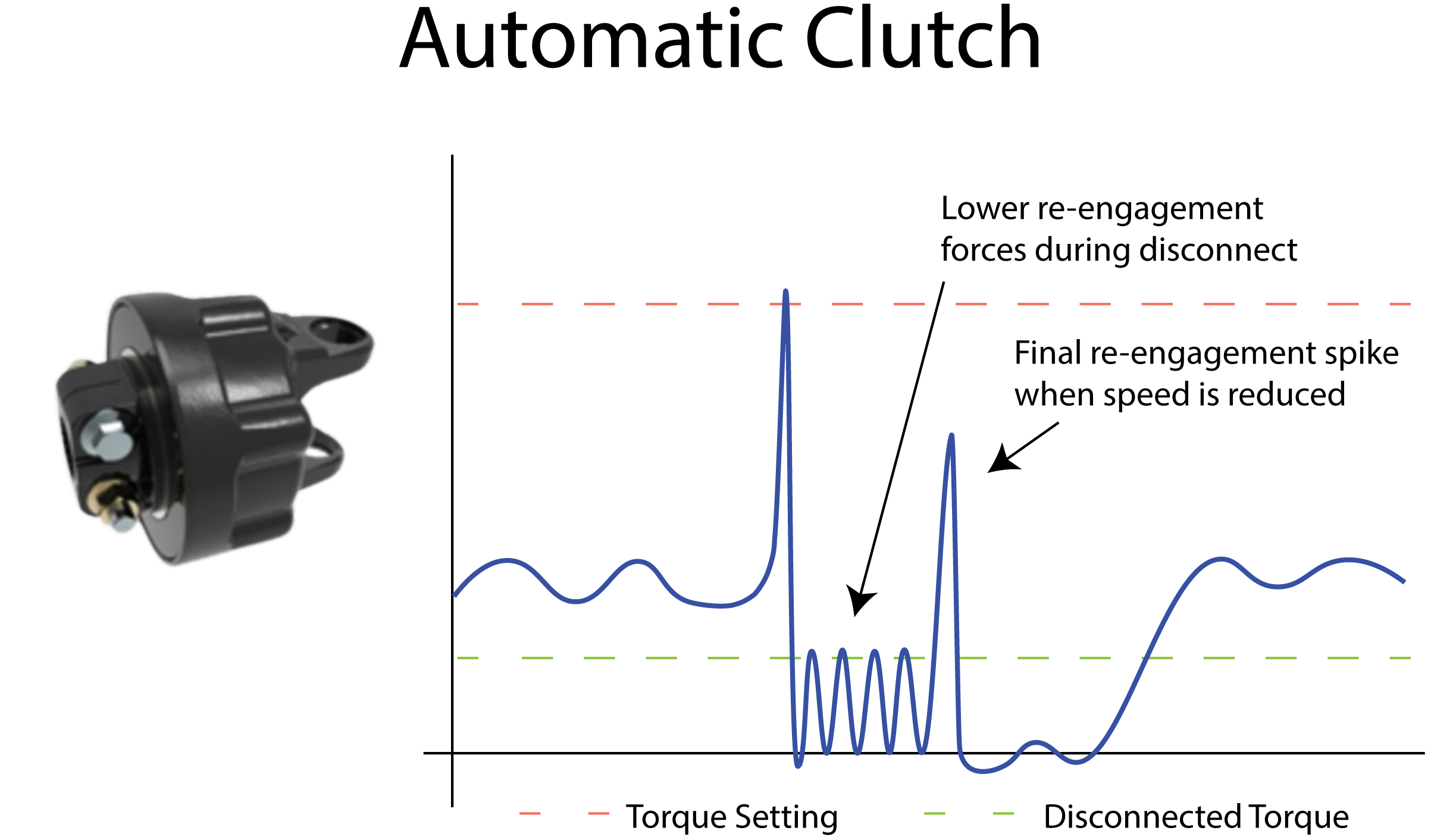

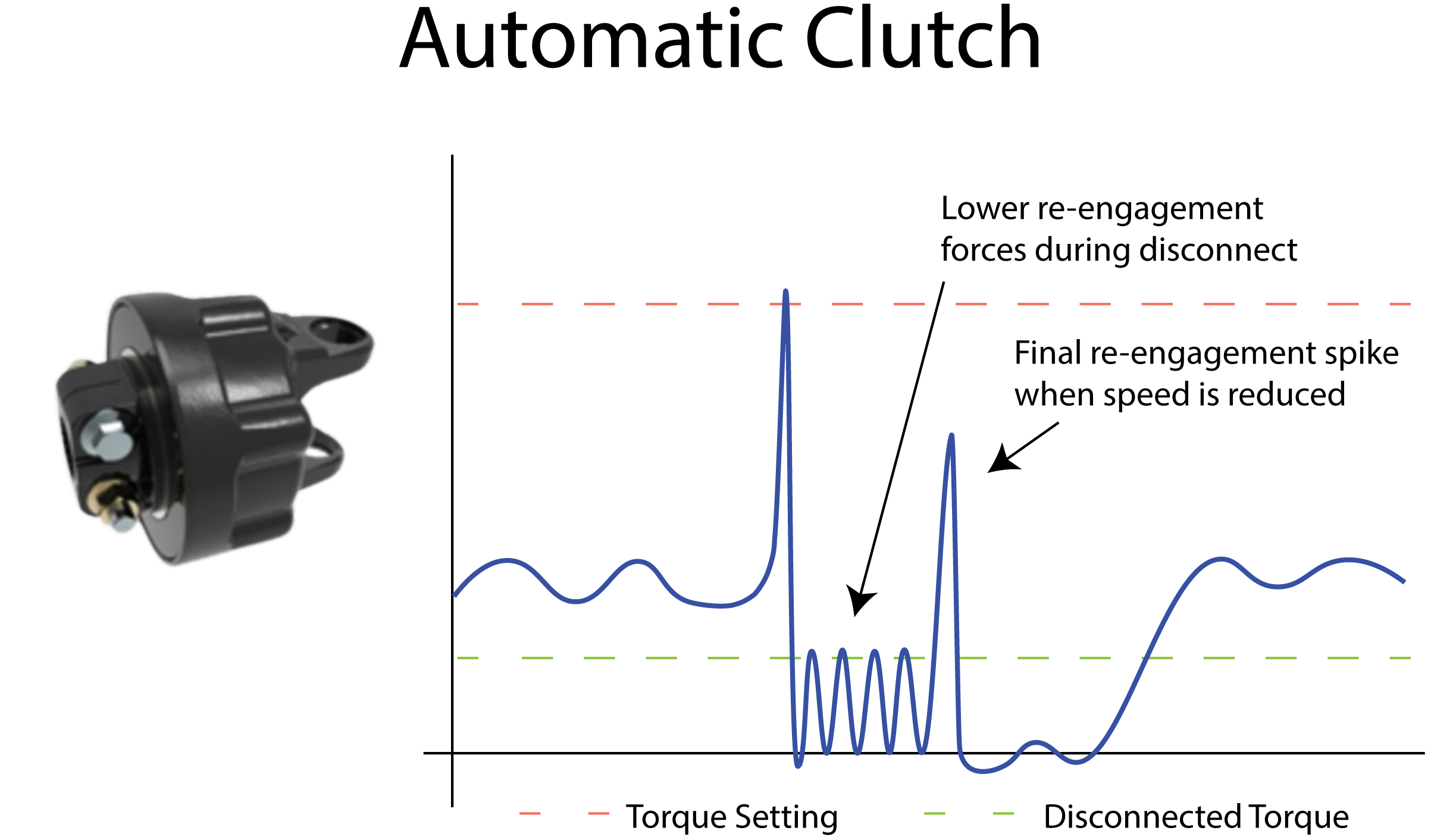

Automatic Clutch

Application examples: Balers, combine headers, combine drives, grain carts, manure spreaders and mixer feeders.

Learn more by reading each brochure:

Compact Automatic – 100 to 1,000 Nm [1,000 to 8850 in-lb]

Modular Automatic – 700 to 2700 Nm [6,000 to 24,000 in-lb]

Integral Automatic – 1,000 to 3,000 Nm [8850 to 26,600 in-lb]

High Torque Automatic – 3,000 to 6,000 Nm [26,600 to 53,100 in-lb]

|

|

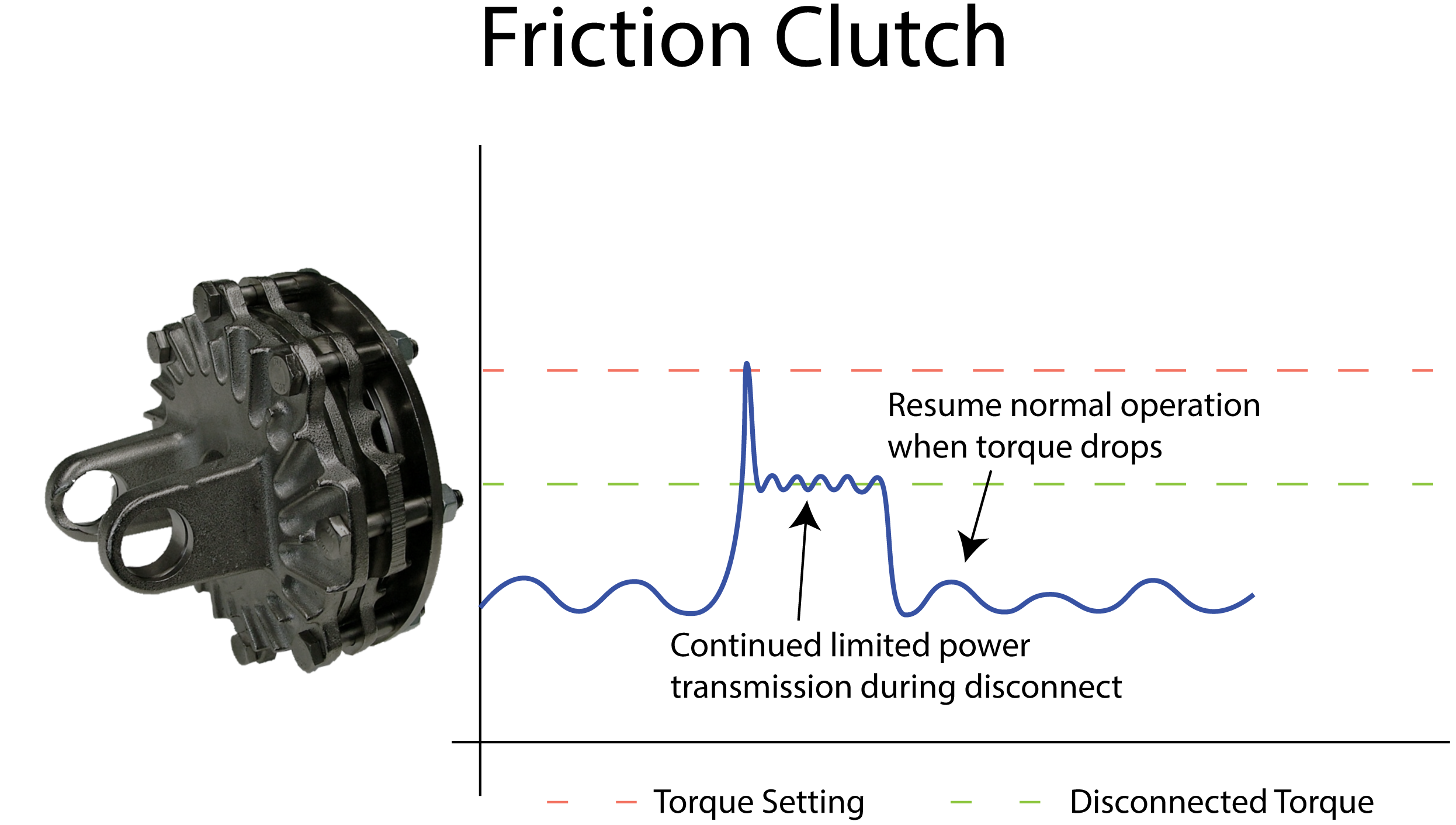

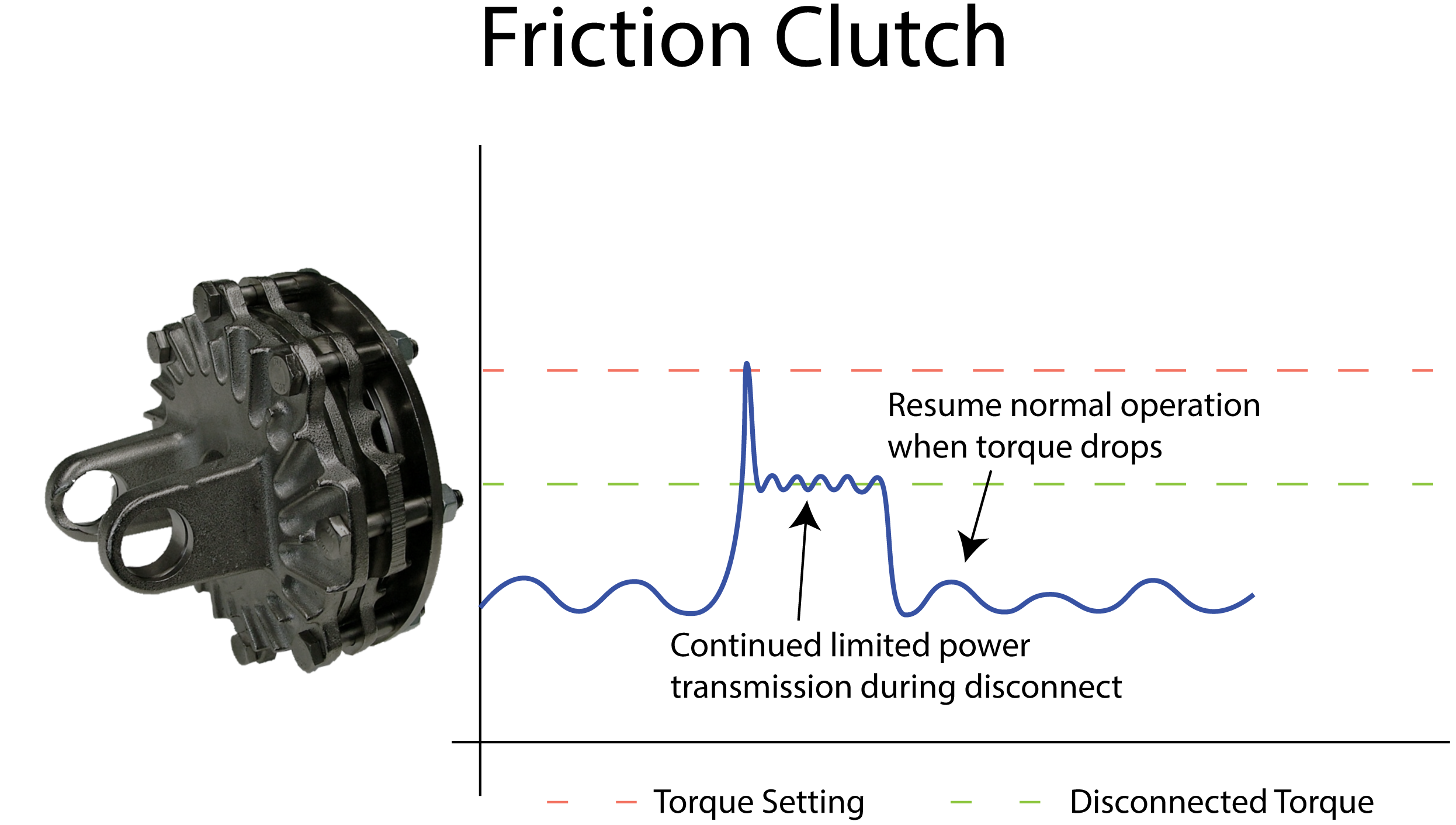

Friction Clutch

Application examples include mower conditioners, rotary cutters, balers, tillers and shredders.

Learn more by reading each product brochure:

Medium Duty Modular Friction Clutch – 450 to 2,000 Nm [4,000 to 18,000 in-lb]

Heavy Duty Modular Friction Clutch – 900 to 2,700 Nm [8,000 to 24,000 in-lb]

Integral Friction Clutch – 1,000 to 2700 Nm [9,000 to 24,000 in-lb]

Flywheel Friction Clutch – 680 – 2700 Nm [6,000 to 24,000 in-lb]

|

|

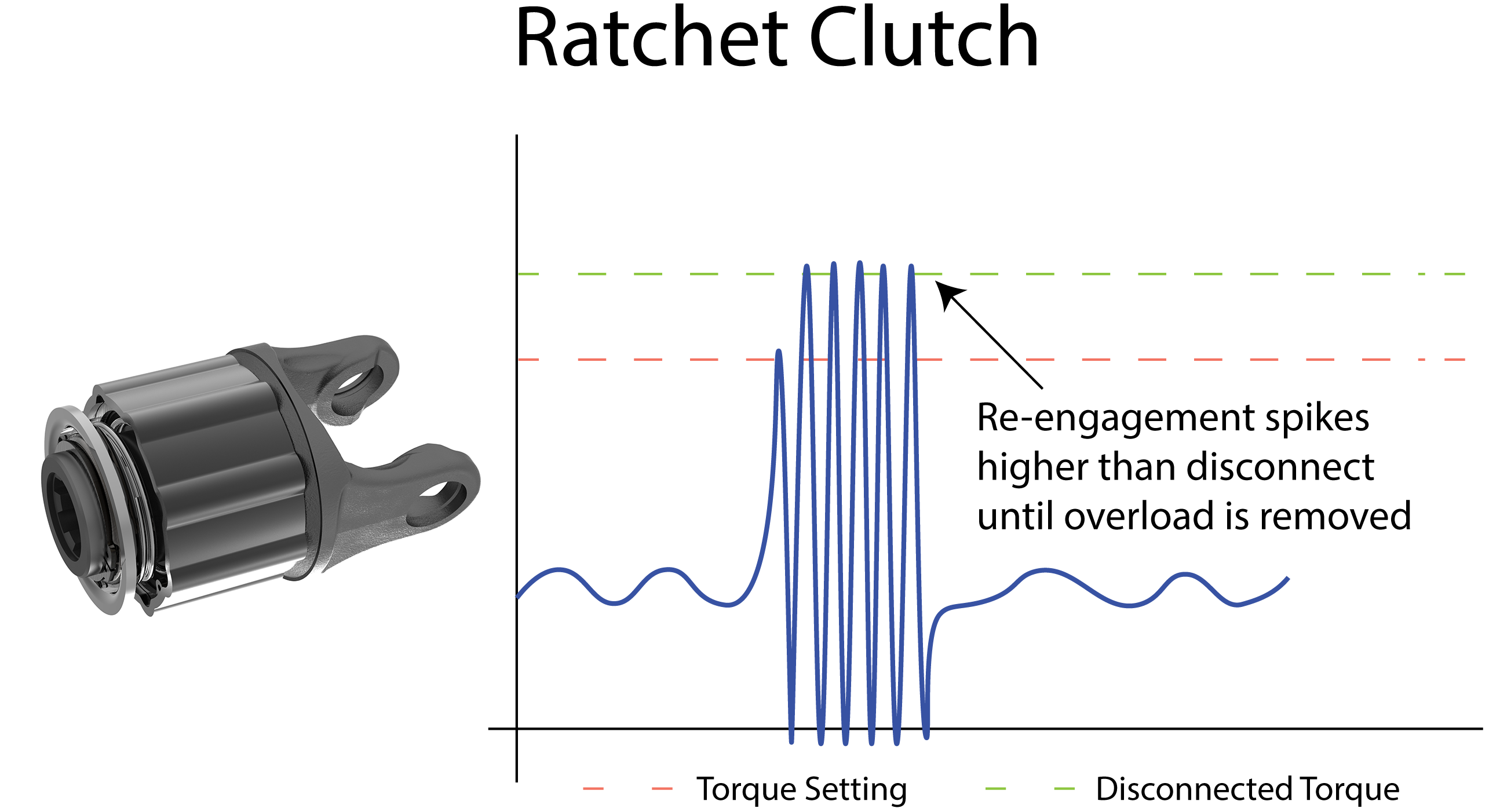

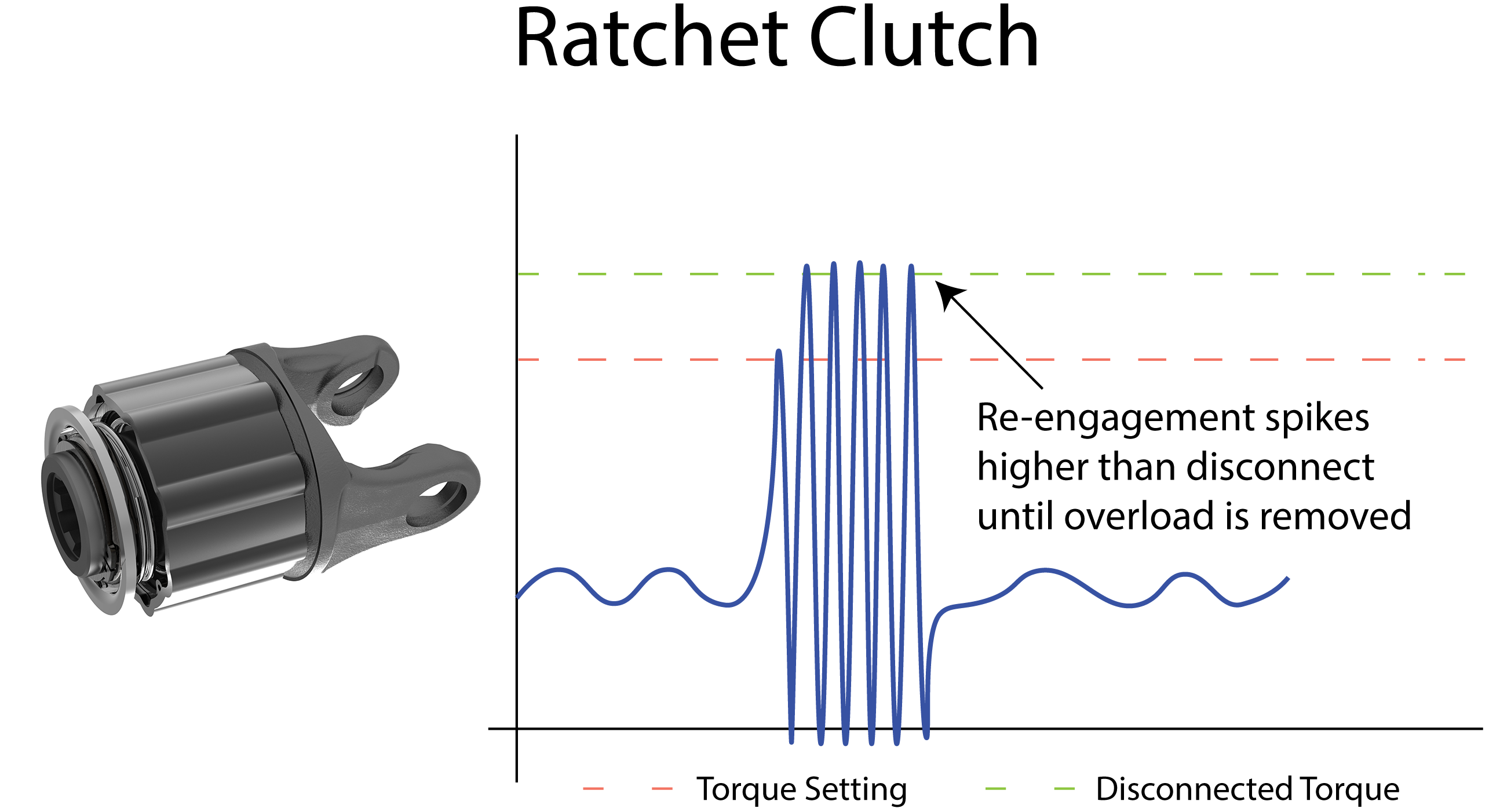

Ratchet Clutch

Application examples include combine headers, combing drives, rakes and tedders.

|

|

Overrunning Clutch

Application examples include balers, rakes, tedders, mixer feeders, woodchippers, manure spreaders and mowers.

Learn more by reading our Overrunning Clutch Brochure.

|

|

Ball Shear

Application examples include snowblowers, grain augers, manure spreaders, mixer feeders and bale processors.

Learn more by reading our Ball Shear Brochure.

|

|

Automatic Clutch

Application examples: Balers, combine headers, combine drives, grain carts, manure spreaders and mixer feeders.

Learn more by reading each brochure:

Compact Automatic – 100 to 1,000 Nm [1,000 to 8850 in-lb]

Modular Automatic – 700 to 2700 Nm [6,000 to 24,000 in-lb]

Integral Automatic – 1,000 to 3,000 Nm [8850 to 26,600 in-lb]

High Torque Automatic – 3,000 to 6,0000 Nm [26,600 to 53,100 in-lb]

|

|

Friction Clutch

Application examples include mower conditioners, rotary cutters, balers, tillers and shredders.

Learn more by reading each product brochure:

Medium Duty Modular Friction Clutch – 450 to 2,000 Nm [4,000 to 18,000 in-lb]

Heavy Duty Modular Friction Clutch – 900 to 2,700 Nm [8,000 to 24,000 in-lb]

Integral Friction Clutch – 1,000 to 2700 Nm [9,000 to 24,000 in-lb]

Flywheel Friction Clutch – 680 – 2700 Nm [6,000 to 24,000 in-lb]

|

|

Ratchet Clutch

Application examples include combine headers, combing drives, rakes and tedders.

|

|

Overrunning Clutch

Application examples include balers, rakes, tedders, mixer feeders, woodchippers, manure spreaders and mowers.

Learn more by reading our Overrunning Clutch Brochure.

|

|

Product Specifications

Contact Us

Product Finder

MARKETS WE SERVE

PRODUCT FINDER

Weasler is part of CentroMotion, a global manufacturing company specializing in friction products, information and control devices, mechanical power transmission products, and thermal and motion controls.

CentroMotion Brands: Carlisle Brake & Friction | CrossControl | Elliott Manufacturing | Gits Mfg. | maximatecc | Power-Packer | Power-Packer North America