Technology and design

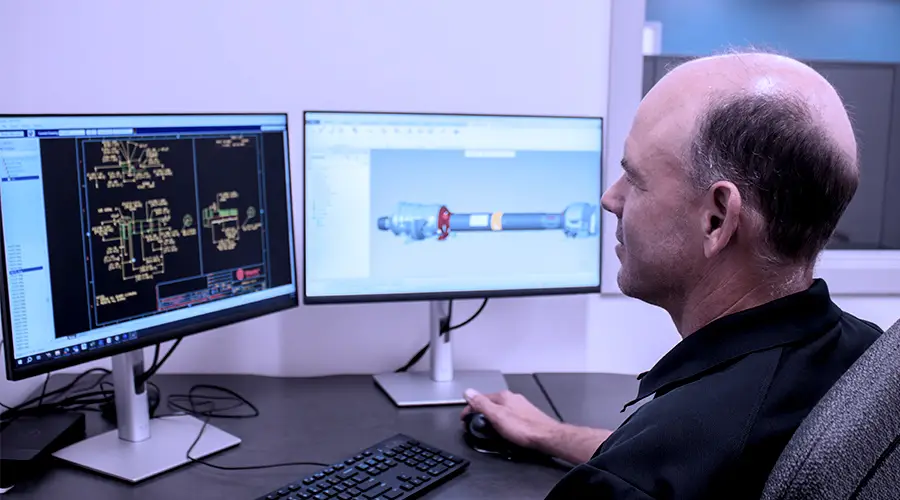

A thorough understanding of your needs lays the groundwork for the best solution. We focus on industry-leading design technology because our priority is agricultural products that last, with limited maintenance. We use modern data acquisition equipment to complement our digital suite of design tools, minimizing development time and maximizing efficiency.

- Creo – A 3D CAD solution that helps accelerate product innovation and build products faster. Used to model the structural integrity of a product under various conditions.

- Finite Element Analysis (FEA) – A computer-aided engineering (CAE) tool used to analyze how a design reacts under real-world conditions.

- Creo Mechanism Dynamics – Extends capabilities to see how different parts interact, testing mechanisms under real-world stresses.

- KISSsoft – A comprehensive and technologically advanced software tool for designing machine elements such as gears, shafts, bearings, bolts, splines and springs.

- Bearing life software – A unique and proprietary calculation process based on our more than 70 years of experience.

- Rapid prototyping – Focused on form, fit and function of a product or component to ensure it fulfills its design goals.

High-tech testing

Our engineering lab houses uniquely configured equipment and a state-of-the-art test lab to evaluate and validate the function, durability and reliability of a design, as well as simulate a part’s use over its entire lifecycle. If needed, our technical team can also partner with you to validate designs directly on your equipment in actual field conditions.

Our in-house tools include:

- Custom test stand fabrication and data acquisition hardware development

- Static torque testing up to 100,000 inch pounds

- Axial testing up to 50,000 pounds

- Dynamometer testing up to 300 horsepower

- Clutch durability testing

- Environmental testing (e.g. low temperature, salt or dust)

- Servo-hydraulic fatigue testing up to 30,000 inch pounds

- Light machining capabilities

- Thermal imaging

- In-field data acquisition capabilities measuring real-time torque and RPM

History of innovation

At Weasler, the desire to innovate is ingrained in our culture. Founder Tony Weasler developed agricultural driveline solutions that have become the gold standard in the industry and shaped agricultural PTO drive shaft technology. We hold numerous patents and ASABE 50 awards for new products, including:

- 50- and 80-degree, wide-angle, constant velocity joints

- 77 Series heavy-duty drive shafts

- High-torque automatic clutch

- Auto-Lok yokes for easy hook-up of a PTO drive shaft

- TorQmaster friction clutches

- TorQmaster automatic, cam-type, cut-out clutches

- “E” (extended lubrication) cross kits with lubrication intervals from 50 to 250 hours

Other Weasler innovations include our patented Easy Lock guard system and fully enclosed, wide-angle, constant velocity guard and integral guard. These guard systems meet or exceed ASABE and ISO standards and are available with CE certification.

New product development

Looking for a unique solution?

If our existing portfolio of configured products doesn’t meet your application needs, our experts will collaborate with you to help solve design system challenges. To determine the best solution, our engineers can:

- Review designs using comprehensive calculation and modeling tools.

- Assist in field testing to determine drive system requirements.

- Assist in lab testing to validate design function, durability and reliability.

The Weasler team is here to answer your questions and get you the information you need. For assistance, contact us today.

Contact Us

Product Finder

MARKETS WE SERVE

PRODUCT FINDER

![]()

Weasler is part of CentroMotion, a global manufacturing company specializing in friction products, information and control devices, mechanical power transmission products, and thermal and motion controls.

CentroMotion Brands: Carlisle Brake & Friction | CrossControl | Elliott Manufacturing | Gits Mfg. | maximatecc | Power-Packer | Power-Packer North America | Weasler