Weasler is a global leader in manufacturing of drive train systems and components for agricultural original equipment manufacturers worldwide, as well as distributing product through a full aftermarket program to a global network.

There are two types of agricultural drivelines or drive shafts:

-

- Primary driveline: Bridges the gap between a tractor and a towed implement allowing for maneuverability while moving through the field, ditches or on the road

- Secondary driveline: Any driveline built into a piece of equipment

Weasler Drive Shafts

Standard

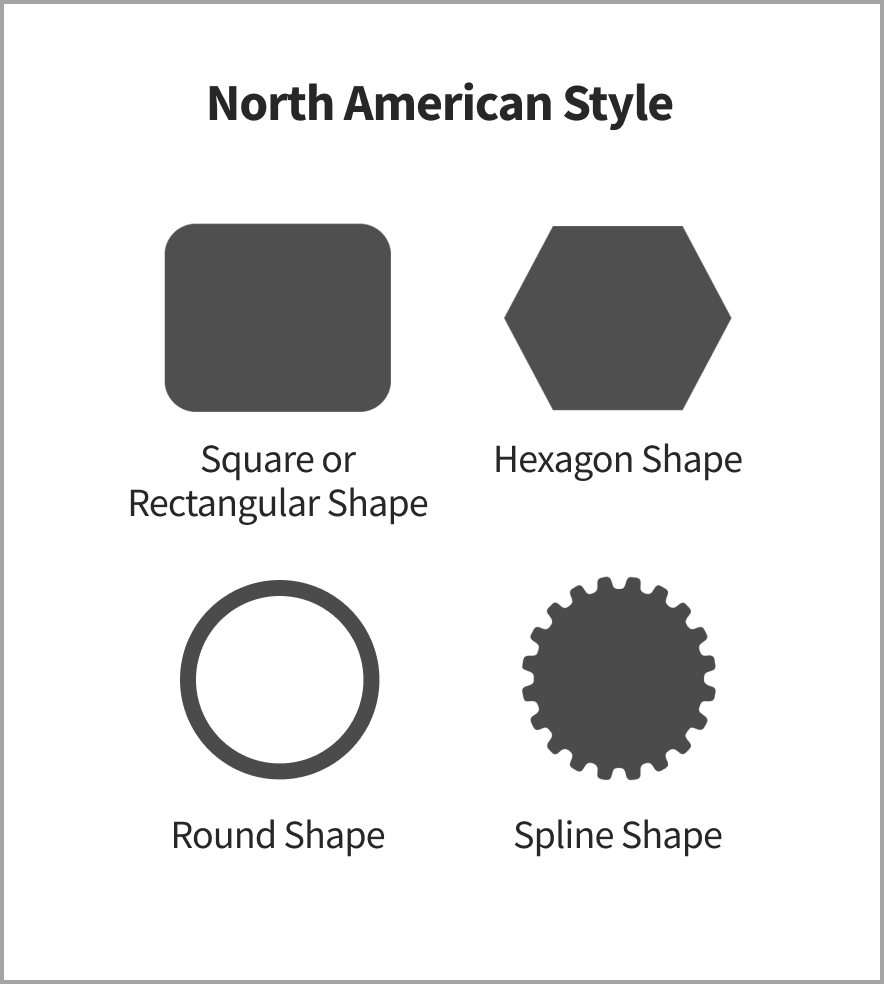

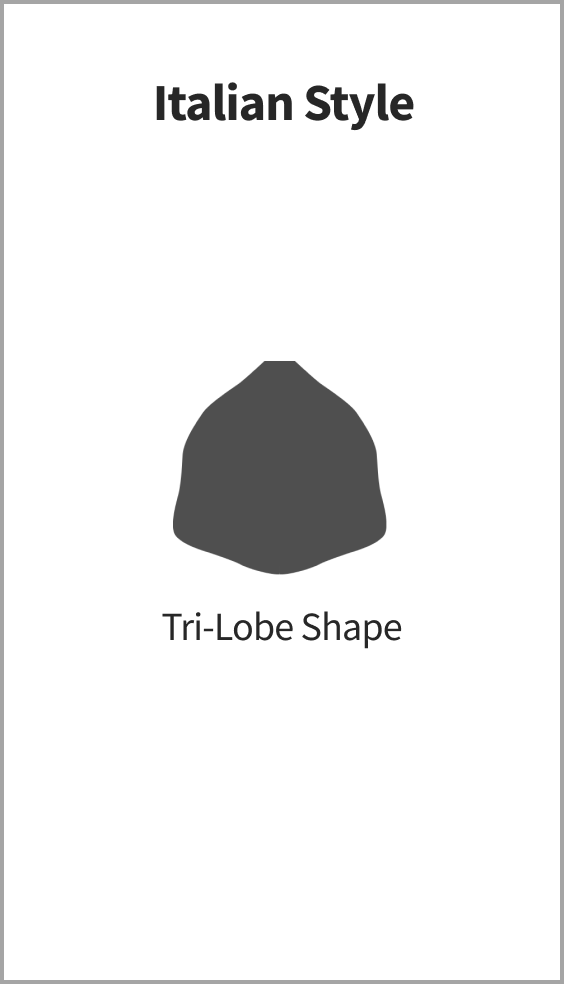

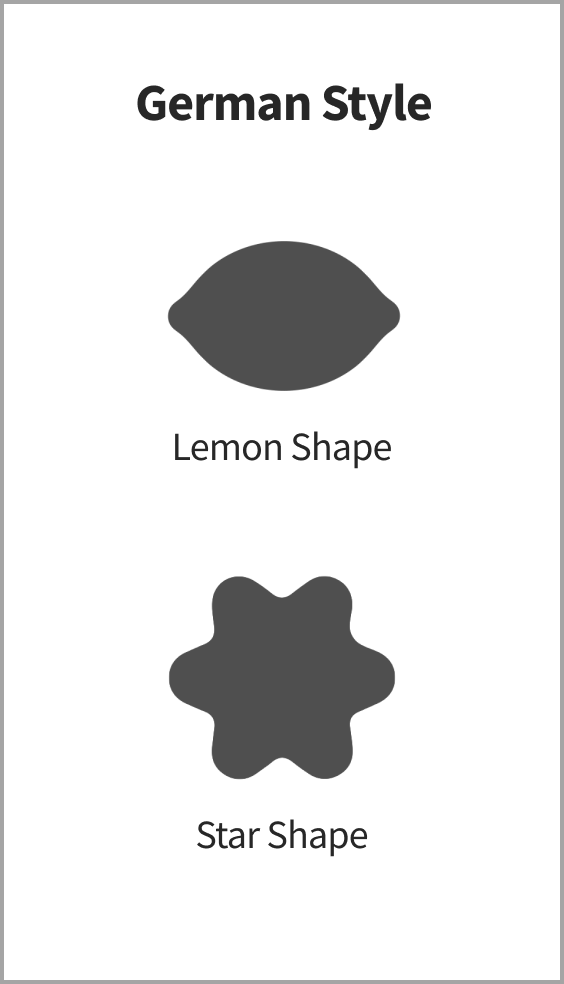

Applications for a Standard drive shaft include rotary cutters, tillers and fertilizer spreaders. Profile telescoping is available in trilobe (North America only) or lemon tubing (EU only).

Learn more by reading the Standard Drive Shaft Brochure.

To find a replacement drive shaft, check our Aftermarket Make/Model Finder.

For essential projects, our Standard drive shaft is a straightforward, off-the-shelf product offering:

- Up to 80 horsepower for occasional duty cycle applications

- Spring-loaded collar tractor yolk

- Easy-to-locate universal joint

- Durable, easy cut-to-length profile telescoping

Classic

Applications for a Classic drive shaft include rotary cutters, combine headers, balers, mower conditioners, mixer feeders or manure spreaders. Profile telescoping is available in Lemon (EU only), Trilobe, Star, Square and Spline.

Learn more by reading the Classic Drive Shaft Brochure.

|

Our Classic drive shaft delivers quality components to ensure you have the power to complete a variety of everyday PTO projects. Key features include:

|

|

Professional

Applications for a Professional drive shaft include combines, combine headers, forage harvesters, balers, mower conditioners and mixer feeders. Profile telescoping is available in star or spline, sleeve, sealed or double-telescoping tube.

Learn more by reading the Professional Drive Shaft Brochure.

|

The Professional drive shaft is a rugged workhorse. Key features include:

|

|

Standard

Applications for a Standard drive shaft include rotary cutters, tillers and fertilizer spreaders. Profile telescoping is available in trilobe (North America only) or lemon tubing (EU only).

Learn more by reading the Standard Drive Shaft Brochure.

To find a replacement drive shaft, check our Aftermarket Make/Model Finder.

For essential projects, our Standard drive shaft is a straightforward, off-the-shelf product offering:

- Up to 80 horsepower for occasional duty cycle applications

- Spring-loaded collar tractor yolk

- Easy-to-locate universal joint

- Durable, easy cut-to-length profile telescoping

Classic

Applications for a Classic drive shaft include rotary cutters, combine headers, balers, mower conditioners, mixer feeders or manure spreaders. Profile telescoping is available in Lemon (EU only), Trilobe, Star, Square and Spline.

Learn more by reading the Classic Drive Shaft Brochure.

|

Our Classic drive shaft delivers quality components to ensure you have the power to complete a variety of everyday PTO projects. Key features include:

|

|

Professional

Applications for a Professional drive shaft include combines, combine headers, forage harvesters, balers, mower conditioners and mixer feeders. Profile telescoping is available in star or spline, sleeve, sealed or double-telescoping tube.

Learn more by reading the Professional Drive Shaft Brochure.

|

The Professional drive shaft is a rugged workhorse. Key features include:

|

|

PTO Identification

Drive shafts are available in North American and profile metric series. Each type includes a variety of components: telescoping shaft, yokes (tube, shaft, tractor and implement), cross and bearing kits and guard.

Product Specifications

| FEATURES | |||

|---|---|---|---|

| Safety | Meets regional ASABE & CEN requirements | Meets regional ASABE & CEN requirements | Meets regional ASABE & CEN requirements |

| Horsepower 540rpm | Up to 80hp | Up to 170hp | Up to 170hp |

| Tractor Yoke Type | Spring-Lok | Spring-Lok, Safety Slide Lock or Auto-Lok | Spring-Lok, Safety Slide Lock or Auto-Lok |

| Telescoping Options | Profile | Profile, Sleeve | Profile, Sleeve, Sealed, Double-Telescoping |

| Constant Velocity Joint | NA | 80° CV Design, 50° CV Design | 80° CV Design, 80° CVE Design, 50° CV Design |

| Universal Joint Maintenance | 8-hour interval | 8-hour, or 50-250-hour interval | 50-250-hour interval, or Maintenance-Free |

| Torque Limiter Type | Friction or Shear | Friction, Shear, or any available | Friction, Shear, or any available |

| Duty Cycle | Occassional | Intermittent | Continuous Use |

| Easy Lock Guard | No | Yes | Yes |

| Example Application | Wing Drive, Rotary Cutters, Tillers, Fertilizer Spreaders, Rakes and Tedders | Mixer Feeders, Grain Carts, Shredders, Headers, Manure Spreaders | Mixer Feeders, Forage Wagons, Balers, Augers, Headers, Combines |

Contact Us

Product Finder

MARKETS WE SERVE

PRODUCT FINDER

![]()

Weasler is part of CentroMotion, a global manufacturing company specializing in friction products, information and control devices, mechanical power transmission products, and thermal and motion controls.

CentroMotion Brands: Carlisle Brake & Friction | CrossControl | Elliott Manufacturing | Gits Mfg. | maximatecc | Power-Packer | Power-Packer North America | Weasler